“Innovative Metal Fabrication Services Transforming Business Operations”

Introduction

In today’s rapidly evolving industrial landscape, businesses across various sectors are continually seeking innovative solutions to enhance productivity, reduce costs, and improve operational efficiency. One area that has seen significant advancements is metal fabrication. From MIG welding to TIG welding, and other specialized techniques, the realm of metal fabrication services is transforming how companies operate. This article delves into the transformative power of innovative metal fabrication services, showcasing their impact on business operations while highlighting essential techniques like mobile welding in Phoenix, arc welding, and plasma welding.

Understanding Metal Fabrication Services

What Are Metal Fabrication Services?

Metal fabrication services refer to a range of processes that involve the construction of Xpress mobile welding Phoenix LLC metal structures by cutting, bending, and assembling. These services can be tailored for various applications across industries such as automotive, construction, aerospace, and more.

Key Processes in Metal Fabrication

The Role of Welding in Metal Fabrication

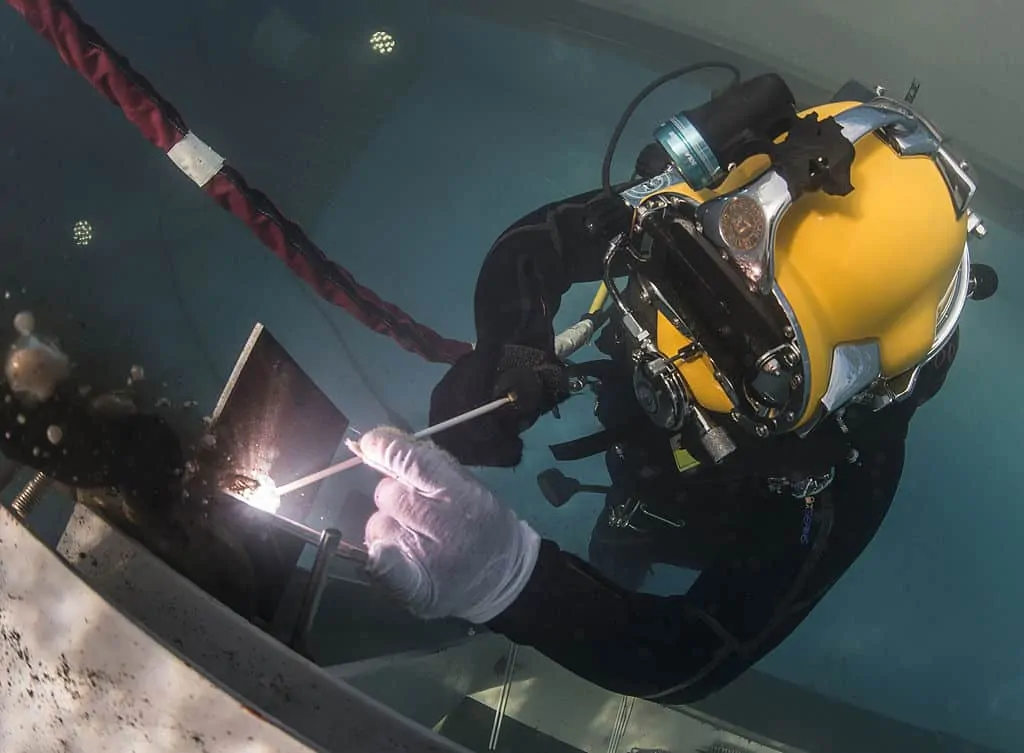

Welding is a critical component of metal fabrication services. It involves melting pieces of metal together to create a strong bond. Different types of welding techniques suit various applications:

- MIG Welding: Known for its speed and versatility.

- TIG Welding: Offers precision for intricate designs.

- Arc Welding: Utilizes electric arcs for powerful welds.

- Plasma Welding: Ideal for thin materials requiring high-quality joints.

Innovative Metal Fabrication Services Transforming Business Operations

Why Innovation Matters in Metal Fabrication

Innovation in metal fabrication leads to improved efficiency, cost savings, and enhanced product quality. As businesses strive for competitive advantages, adopting cutting-edge technologies becomes imperative.

Technological Advancements in Metal Fabrication

Recent advancements include automation through robotics, 3D printing capabilities for rapid prototyping, and advanced software for precise design modeling.

Benefits of Embracing Technology

- Increased accuracy

- Reduced lead times

- Lower labor costs

- Enhanced safety measures

Mobile Welding Services: A Game Changer

In urban centers like Phoenix, mobile welding services have emerged as a practical solution for businesses needing on-site repairs or custom fabrications without the hassle of transporting materials.

Advantages of Mobile Welding

- Convenience

- Time-saving

- Cost-effective solutions

Safety Measures in Metal Fabrication

Importance of Welding Safety Standards

Safety cannot be overlooked in any aspect of metal fabrication. Proper safety protocols ensure worker protection and minimize accidents.

Essential Safety Equipment for Welders

Training Programs

Regular training programs are crucial to educate employees about safety procedures and equipment usage.

How Innovative Metal Fabrication Enhances Productivity

Streamlining Operations with Efficient Processes

By adopting innovative metal fabrication techniques, businesses can streamline their operations significantly:

- Faster production times

- More reliable supply chains

- Improved inventory management practices

Case Studies Highlighting Transformation Through Innovation

Challenges Facing the Metal Fabrication Industry

Addressing Skill Gaps in the Workforce

As technology advances rapidly, there is often a gap between available skills and industry requirements.

Training Future Generations

Investing in education programs helps cultivate skilled workers proficient in modern techniques like plasma welding and advanced MIG/TIG processes.

Exploring Various Welding Techniques

MIG Welding Explained

Metal Inert Gas (MIG) welding is widely used due to its efficiency and ease of use.

Applications of MIG Welding

Ideal for thin materials such as aluminum or stainless steel.

TIG Welding Overview

Tungsten Inert Gas (TIG) welding allows for greater control over welds.

When to Use TIG Welding?

Best suited for stainless steel or when high precision is required.

Welding Equipment Essentials

Choosing The Right Equipment For Your Needs

Selecting suitable equipment is paramount for successful projects within metal fabrication services:

Frequently Asked Questions (FAQs)

- MIG welding uses a consumable wire electrode while TIG employs a non-consumable tungsten electrode offering better control over welds but requires more skill.

- Mobile welding offers flexibility and convenience; it allows on-site repairs without transporting materials which saves time and money.

- Commonly used in heavy machinery repair work or structural components due to its robust bonding capabilities.

- Plasma welding provides higher heat concentration allowing it to work with thinner materials more effectively than some traditional methods.

- Regular training sessions on equipment usage, mandatory protective gear wearing, maintaining clean workspaces among others help ensure safety standards are met.

- Yes! By streamlining processes through technology integration businesses can achieve faster turnaround times leading directly to cost reductions overall!

Conclusion

As we’ve explored throughout this article on “Innovative Metal Fabrication Services Transforming Business Operations,” it’s evident that these services play an integral role across numerous industries today—enhancing productivity while ensuring quality standards remain high! The importance placed on innovation cannot be understated; embracing new technologies not only optimizes existing workflows but also prepares organizations capable enough weather future challenges ahead!

In an ever-evolving landscape where competition grows fiercer each day—investments made towards enhancing capabilities through advanced methodologies such as MIG/TIG/Arc/Plasma will undoubtedly yield long-term benefits! So why wait? Explore what innovative fabrication can do—unlock potential today!

This lengthy guide aims not just informatively yet persuasively highlight how integral effective practices within this dynamic field serve transform operations—equipping readers with knowledge necessary achieve success!